Chapter1. What is the Flatbed Semi Trailer

Chapter2. What are the main components of a 40ft flatbed trailer?

2.1 40ft flatbed trailer platform

2.2 40ft flatbed trailer supporting structure

2.3 40ft flatbed trailer chassis

Chapter3. What is the advantage of a 40 ft Flatbed Trailer?

Chapter4. How to fix the container on the 40ft Flatbed Trailer?

Chapter1. What is the Flatbed Semi Trailer

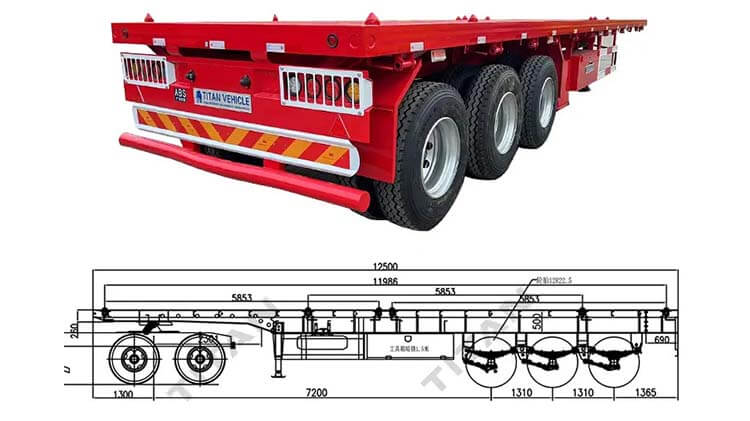

40ft flatbed trailer is a semi-trailer with a platructure, mainly used to transport containers of different sizes, mainly used in import and export trade, logistics and transportation and other fields. Its main structure consists of chassis, wheels, tires, suspension systems, It is composed of hinge mechanism, landing gear and container brackets.

Structurally, the body part of the Flatbed Semi Trailer is flat and equipped with twist locks to fix the container, which can adapt to various types of container transportation. Its chassis is usually made of high-strength steel, which has strong durability and can withstand large load pressure. At the same time, the Jiping semi-trailer also has good adaptability and flexibility, and can be refitted and adjusted according to different transportation needs to meet the requirements of different occasions.

In short, 40ft flatbed trailer for sale is an efficient, flexible and reliable cargo transportation tool. It can quickly, safely and efficiently complete the cargo transportation task, and ensure the safety of the cargo during transportation. It has a strong application value and development prospects. In the future development, the Jiping semi-trailer will continue to exert its superior performance and functions, and provide more efficient and convenient solutions for the transportation of goods in all walks of life.

40ft flatbed trailer Ideas | Semi Flatbed Trailer for Sale in Madagascar

Chapter2. What are the main components of a 40ft flatbed trailer?

2.1 40ft flatbed trailer platform

The platform part of the container flat semi-trailer refers to the cargo area of the semi-trailer. The following is the introduction of the platform part of the six container flat semi-trailers:

1. The platform part of the container flatbed trailer is usually made of high-strength steel, which has the characteristics of strong bearing capacity and good durability.

2. The length of the platform part of the container flat bed trailer is usually between 12 meters and 15 meters, which can be customized according to the size of the container and other transportation needs of customers.

3. The surface of the platform part of the semi flatbed trailer for sale is usually covered with anti-skid texture, which can increase the stability of the goods and avoid the sliding of the goods during transportation. At the same time, it can also reduce the contact area between the container and the platform and reduce the wear and tear of the platform, thereby increasing The service life of the semi-trailer.

4. The platform part of the container 40ft Flatbed Trailer is usually equipped with 12 fixed and movable high-quality container twist locks, which are used to fix containers of different sizes.

40ft flatbed trailer Ideas | Semi Flatbed Trailer for Sale in Madagascar

2.2 40ft flatbed trailer supporting structure

The supporting structure is the core part of the 40ft flatbed trailer, which is responsible for supporting the platform and cargo.It includes the main beam and beams under the platform. It is usually made of welded steel and has good bearing capacity and seismic performance.

40ft flatbed trailer Ideas | Semi Flatbed Trailer for Sale in Madagascar

2.3 40ft flatbed trailer chassis

Chassis including tires, axles, suspension, and landing gear

The landing gear can help the vehicle to park stably, load and unload goods.

This model can well protect the goods and prevent them from being shaken, collided and damaged during transportation.

The chassis is the main supporting structure of the 40ft flatbed trailer for sale. It is usually composed of axles, suspension systems, brake systems and other parts, and has good stability and driving performance.

40ft flatbed trailer Ideas | Semi Flatbed Trailer for Sale in Madagascar

Chapter3. What is the advantage of a 40ft Flatbed Trailer?

1. It can quickly and safely load and unload goods, because the container can be directly loaded on the car body, which reduces the workload of manual handling and improves the efficiency of loading and unloading.

2. Since the chassis of this model is made of high-strength materials, it has strong bearing capacity and good durability, and can adapt to various road conditions and loads.

3. The 40ft flatbed trailer has the characteristics of good flexibility during transportation, and can be flexibly adjusted according to different cargo loads to meet the needs of different loads

4.For the use of flat deck trailers, the following points need to be paid attention to:

Check the vehicle and keep it in a good state of maintenance to ensure that the vehicle can be driven safely and stably.

Drivers must hold corresponding professional driver's licenses and qualification certificates, and have undergone professional training and assessment.

When loading goods, it needs to be arranged according to different types, sizes and weights of goods, and the container should be fixed firmly with ropes or other fixing devices above the container to avoid accidents during transportation.

In the process of driving and parking, it is necessary to maintain the stability of the vehicle, and pay special attention to factors such as curves, slopes, road conditions, etc., to avoid loss of control of the vehicle or damage to the cargo due to improper manipulation.

In short, the container 40ft flatbed trailer is a very practical professional transport vehicle with the advantages of high efficiency, safety and reliability, and is suitable for various types of container cargo transportation needs.

40ft flatbed trailer Ideas | Semi Flatbed Trailer for Sale in Madagascar

Chapter4. How to fix the container on the 40ft Flatbed Trailer?

The container flatbed trailer is a semi-trailer specially used for transporting containers. It uses special fixing devices to fix the container on the body to ensure the safety and stability during transportation. The following are the main methods for fixing the container on the 3 axle flatbed trailer:

1. Bracket fixing method: This method is the most commonly used fixing method, which fixes the container on the semi-trailer platform through the bracket. The bracket is usually divided into three parts: front, middle and rear. The front bracket is used to fix the front end of the container, the middle bracket is used to support the middle part of the container, and the rear bracket is used to fix the rear end of the container. Through the support and fixing of the bracket, the container can be firmly fixed on the flatbed of the semi-trailer to ensure the stability and safety during transportation.

2. Tie rod fixing method: This method is another commonly used fixing method, which fixes the container on the semi-trailer platform through a tie rod. The tie rods are usually divided into front and rear parts. The front tie rods are used to fix the front end of the container, and the rear tie rods are used to fix the rear end of the container. Through the pulling force and fixing of the tie rod, the container can be firmly fixed on the semi-trailer flatbed to ensure the stability and safety during transportation.

3. Manual rope fixing method: This method is a simple and practical fixing method, which fixes the container on the semi-trailer platform through manual ropes. The rope is fixed on the flat plate through buckles and fixing rings. By manually adjusting the tension and length of the rope, the container can be firmly fixed on the flat plate to ensure stability and safety during transportation.

In short, there are various fixing methods for container 40ft Flatbed Trailers, and different fixing methods are suitable for different container sizes and weights. During use, it is necessary to select an appropriate fixing method according to the actual situation, and operate in strict accordance with the fixing requirements to ensure safety and stability during transportation.